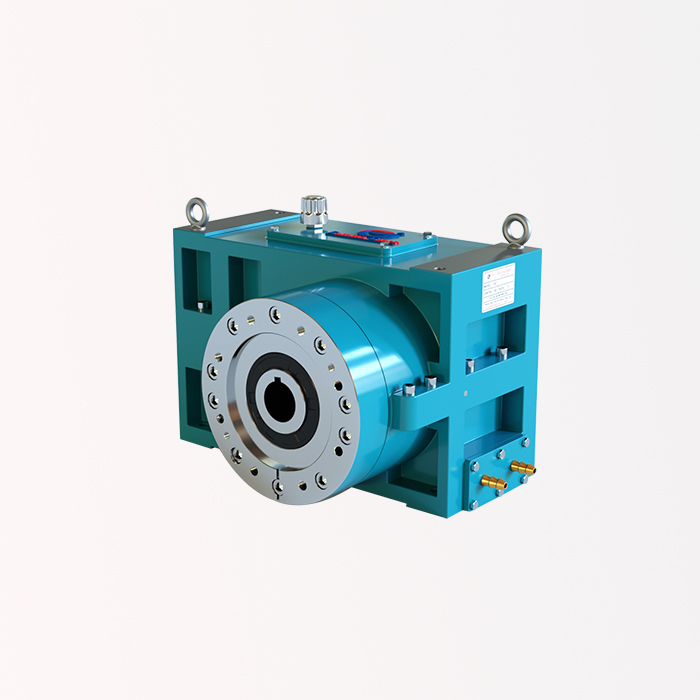

The Functioning of the Extruder Helical Gearbox in Oil Mill Machinery

At, Worm Reduction Gearbox Manufacturer Gamma Gears, an extruder helical gearbox is a specific power transmission device used in various industries, including oil mills. In oil mills, the helical gearbox is connected to the extruder, which processes raw seeds such as soybeans, sunflower seeds, or cotton seeds. Oil mills dependent on mechanical oil extraction processes, where raw seeds are crushed or pressed to release oil. The extruder works a fundamental role in this procedure.

The Best Power Transmission System:

The extruder helical gearbox is designed to handle high torque and provides the necessary speed reduction to drive the extruder’s screw mechanism. It transmits power from the motor to the extruder, ensuring that the equipment operates at the precise speed for optimum oil extraction.

Accuracy and Ensuring Operation Efficiency:

The helical gears used in the gearbox are designed for smooth engagement and precise power transmission. This reduces the machine-driven losses connected with other gear types, enhancing the complete efficiency of the oil mill machinery. The result is higher quantity and reduced energy consumption, serious working elements in all-encompassing oil extraction.

Application-specific Load Distribution and Resilience:

Helical gears are known for their ability to distribute loads consistently across the gear teeth. This improves the gearbox’s lifespan and confirms that the extruder operates smoothly under heavy loads. The strong design of extruder duty helical gearboxes with universal mounting ensures that they can handle the constant strain of oil extraction operations, reducing interruption and maintenance costs.

Reduced Excessive Vibration and Noise:

One of the main advantages of helical gears is their ability to operate with minimal noise and vibration compared to other gear types. This is predominantly advantageous in an industrial setting like an oil mill, where sustained exposure to high noise levels can impact both the equipment’s prolonged existence and the operators’ functioning settings.

Benefits of Using an Extruder Helical Gearbox in Oil Mill Machinery

Improved Efficiency:

The smooth and quiet operation of helical gears means that energy is transferred with minimal loss, resulting in higher complete system efficiency. Oil mills can development more raw materials with less energy consumption, important to cost savings in the long run.

Better-quality Reliability:

The design of helical gears ensures that they are extremely trustworthy, even under heavy loads. This is crucial in oil extraction processes, where consistency is key. By reducing the possibility of gear failures, the extruder helical gearbox helps minimize downtime and increases the operating effectiveness of the oil mill.

Advanced Torque Handling Capability:

The extruder requires substantial torque to crush and press raw seeds. Helical gearboxes are capable of handling high torque, making them supreme for this purpose. They confirm that the extruder operates at the right force to extract oil without overstressing the components.

Permanency and Reduced Maintenance:

The durable construction of extruder duty helical gearboxes with universal mounting means they have a longer lifespan, reducing the need for frequent maintenance or part replacement. This is an essential factor for oil mill operations that run uninterruptedly, as less downtime translates into higher efficiency.