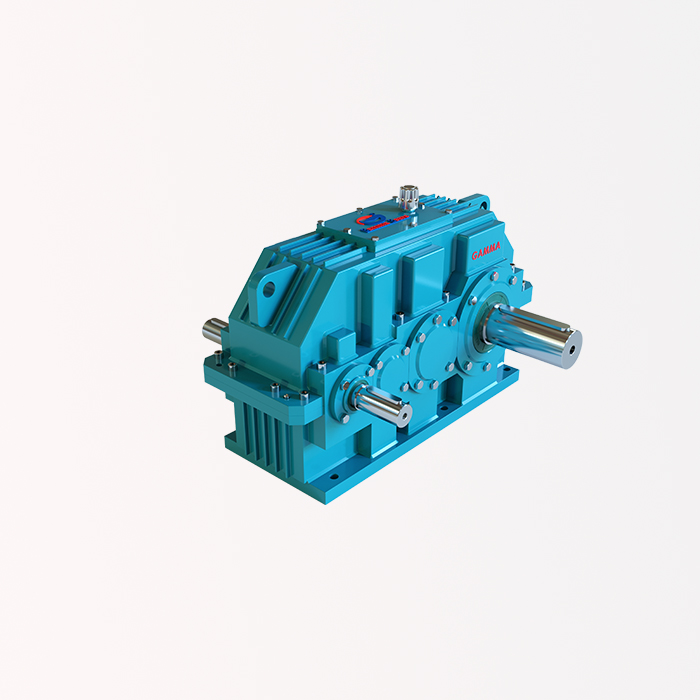

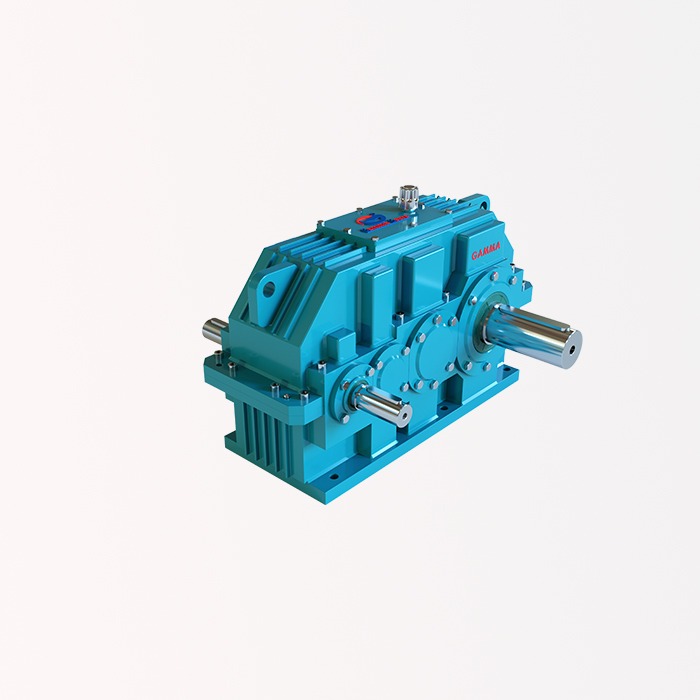

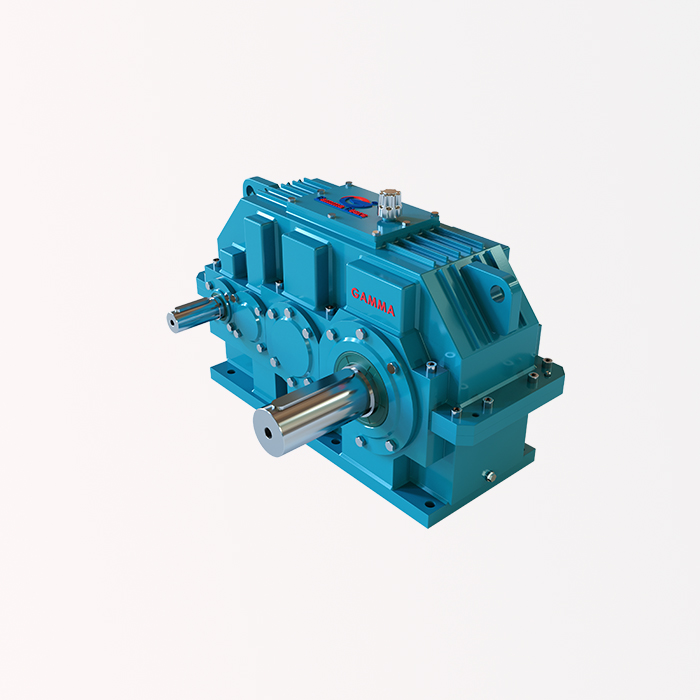

Gamma Gears is experts in manufacturing helical gearboxes which operate on modular concept of construction in compliance with respect to sizes and dimensions. This technology enables economic mass production, massive maintenance of stocks, amazing delivery period and convenience of servicing.

Helical gears function further efficiently and silently evaluated to spur gears because of the way the helical teeth interact. The teeth on a helical gear cut at a position to the facade of the gear. While two of the teeth start to connect, the contact is regular starting at one end of the tooth and sustaining get in touch with as the gear rotates into completely interactions. The load corresponding to the shaft of the gear varies directly with the degree of digression of helix direction. Helical is the mainly frequently used gear in transmissions. Helical also produce large amounts of power and use bearings to facilitate maintain the thrust load. Helical gearboxes drive can be used to adjust the rotation angle by specific degree angle.

Helical gear manufacturing Gamma Gear’s highly designed helical gearboxes are designed with latest techniques. In Ahmedabad, Gujarat, India Gamma Gears use good quality primary ingredients to produce premium quality aforementioned gearbox. Our helical gearboxes products are energy efficient and thus reduce running cost to substantial extent. Our helical gearbox is dimensionally interchangeable with other manufacturer. Oil tight gear head enables motor removal without spillage.

Helical gearboxes, with their exceptional design and extraordinary performance, are necessary components in numerous industrial engineering applications. From heavy-duty machinery to intricate robotics, these helical gear reducers dedicate a crucial role in transmitting power successfully and smoothly. Helical gearboxes are essential components in various industries, revolutionizing power transmission with their efficiency, precision, and durability. Their unique design, coupled with a range of configurations, allows them to adapt to diverse applications and demands. Considerate the profits and concerns of these helical reduction gearboxes empowers engineers and technicians to select the perfect solution for their specific requirements, ensuring optimal performance and dependability.

The significant feature of a helical gearbox is the helical shape of its gears. Visualize a gear with teeth that are not conventional but angled like a screw – that’s a helical gear. This angled tooth design offers several advantages over old-fashioned spur gears:

Smoother Mechanical Operation: The angled teeth engage progressively, foremost to less noise and vibration for the duration of operation. This translates to a more contented and well-organized working environment.

High Work Load Capability: The increased contact area between helical teeth distributes the load more regularly, allowing the gearbox to handle heavier loads deprived of compromising enactment.

Reduced Repercussion: The overlapping teeth minimize the gaps between gears, reducing backlash and improving positioning accuracy. This is crucial for applications requiring precise control and movement.

Helical gearboxes are extensively used in a different range of industries:

Industrial Engineering Manufacturing: In machinery like lathes, milling machines, and extruders, helical gearboxes ensure accurate and controlling operation.

Tough Heavy Material Handling: Cranes, conveyors, and forklifts rely on the stoutness of helical gearboxes for heavy lifting and accurate movement.

Automotive: Helical gearboxes are vital in transmissions, steering systems, and electric vehicles, offering efficient power transfer and smooth operation.

Robotics: Precision and efficiency are paramount in robotics, and helical gearboxes provide the ideal solution for accurate and controlled movements.

Gearboxes have found use in a wide variety of different applications, such as wind turbines. Transmissions are also used in agricultural, industrial, construction, mining and automotive equipment. In addition to ordinary transmission equipped with gears, such gear makes broad use of the hydrostatic drive and electrical changeable speed drives. And, the best industrial example is here that is helical speed reducer.

Gamma Gears is one of the top helical gearbox manufacturers in Ahmedabad, Gujarat, India.

High Efficiency: Due to the smooth operation and minimal losses, helical gearboxes boast high efficiency, minimizing energy waste. In the helical spur gear mechanical design, the high number of teeth involved rationally helps a minimum level of friction and an associated minimum degenerated drive loss in the transfer process. After all at the end output, in turn, in high efficiency and reduced energy use overall.

Durable Construction: Robust design and high-quality materials ensure longevity and reliability even under demanding conditions.

Low Maintenance: The robust construction and smooth operation minimize wear and tear, reducing maintenance requirements and downtime.

Superior Load-carrying ability: Helical gearboxes are more load-intensive compared to gearboxes. Helical gearboxes have improved torque transmission volume and can take advanced loads deprived of compromising performance.

Improved Alignment Capabilities: Helical gearboxes have high shaft misalignment capabilities compared to worm gearboxes. In turn, reduces the quantity of energy required in the assemblage process for precise alignment.

Versatile Applications: Helical gearboxes adapt to diverse applications, ranging from small-scale tasks to large-scale industrial operations.

WhatsApp us