Helical Gearboxes Are a Key Essential Component in Heavy-Duty Conveyor Systems

Helical gearboxes are supporting the necessary torque and speed reduction to efficiently move heavy loads across significant distances. Their design, employing helical gears instead of spur gears, offers several significant advantages. The inherent smoothness of helical gear meshing minimizes noise and vibration, contributing to a longer operational lifespan and a more constant working environment. This reduced vibration is particularly vital in heavy-duty applications where large, possibly unbalanced loads are being transported, preventing premature wear and tear on the entire conveyor system and reducing the risk of failure. From Gamma Gears helical gear’s geometry allows for a higher load-carrying capacity, making them ideal for the demanding conditions encountered in heavy industry.

The Specific Choice of a Helical Gearbox for a Heavy-Duty Conveyor

The primary factors include the conveyor’s overall capacity, the weight and dimensions of the conveyed materials, the required conveying speed, and the anticipated operating environment. Environmental conditions, such as exposure to dust, moisture, or extreme temperatures, will significantly influence the choice of gearbox materials and protective coatings. By Gamma Gears high skilled engineers support for precise calculation of the torque requirements is top to avoid overloading the gearbox and ensuring trustworthy performance throughout the conveyor’s operational life. This requires a thorough understanding of the frictional forces involved and the anticipated variations in load distribution.

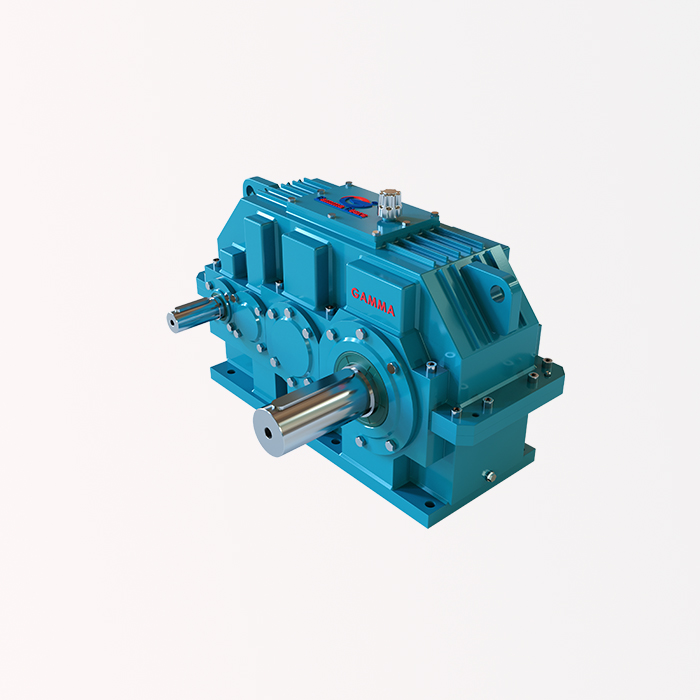

Durability of High Output Torque Wide Ratio Foot Mounting Horizontal Helical Gearbox Is the Most Supreme

Heavy-duty conveyors typically operate mostly in harsh conditions involving continuous operation and significant stress. Within accuracy parameters and high-quality helical gearbox are engineered with robust materials such as hardened steel to withstand these demands. Gamma Gears’s long years of industrial experience and precision manufacturing techniques ensure accurate gear meshing and minimal backlash, further contributing to the gearbox’s extended lifespan and reliability. Regular maintenance, including lubrication and inspection, is crucial in maximizing the service life of the gearbox and preventing premature failure, thereby minimizing downtime and safeguarding the overall productivity of the conveyor system.

The Efficiency of a Helical Gearbox Is Important For Heavy-Duty Conveyor Systems Applications

A high-efficiency gearbox minimizes energy waste, translating to lower operating costs and a reduced environmental footprint. Up-to-date helical gearboxes often incorporate advanced design features such as optimized gear profiles and improved lubrication systems to enhance their efficiency. This increased efficiency contributes not only to cost savings but also to a more supportable operation, aligning with the growing emphasis on environmentally responsible industrial practices. Outside the core performance metrics, the ease of installation and maintenance also plays a vital role in the selection. At, Gamma Gears, a well-designed helical gearbox integrate seamlessly into the overall conveyor system. Openness of key components for lubrication and inspection allows for simplified maintenance procedures, reducing downtime and enhancing operational efficiency. Our in-depth machinery mechanical calculations and simulations are often used to decide the optimal ratio based on the specific requirements of the conveyor system and the expected operating parameters. This comprehensive analysis is crucial to ensure the long-term reliability and smooth operation of the conveyor.

Proper Lubrication is Essential for Helical Gearbox, Especially in the Usage of Heavy-Duty Conveyor System

Regular lubrication schedules should be implemented to maintain an adequate supply of high-quality lubricant between the gear teeth, preventing excessive friction and wear. The choice of lubricant depends on several factors, including the operating temperature range, the load conditions, and the specific materials used in the gearbox construction. Systematic monitoring of the lubricant’s condition is also vital to classify potential issues before they escalate into major problems. The mounting arrangement of the helical gearbox is another key aspect to consider during the selection process. Gamma Gears helical gearbox is securely mounted to the conveyor frame to prevent vibrations and misalignment. Numerous mounting options are available, including foot-mounted, flange-mounted, and shaft-mounted configurations. The choice of mounting method depends on the specific layout of the conveyor system and the overall structural design.

Send your high output torque wide ratio foot mounting horizontal helical gearbox requirements to Gamma Gears is world’s best worm reduction gearbox manufacturing company.