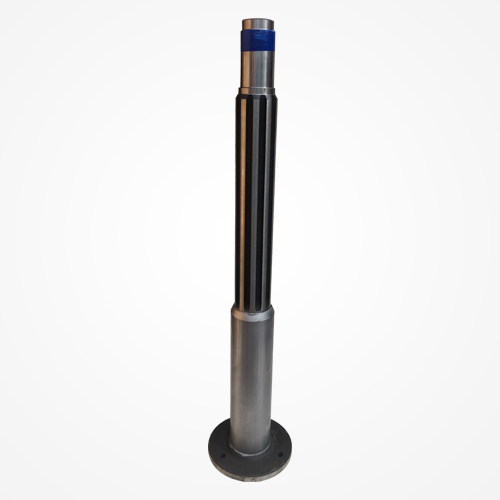

A cyclical set of axial lock points coordinated with keys that are machined into a shaft structures a spline shaft. Splines are mostly used in an arrangement of one internal and one external spline to transmit maximum torque. Gamma Gears manufacture high quality splines which are both cold rolled form and cut roll as per the requirement. Manufacturing capabilities include the production of splined shafts for axles, power transmission, gearboxes and other motion control applications etc. Computerized machines enables our manufacturing team in flexibility to make machine or cold form spline shafts, which are wide-ranging in diameter, specific by clients for their handling.

Gamma Gears is reckoned as one of the top manufacturers of spline shafts based in India. Updated with research and development and modern facilities, we provide top-notch quality spline shafts in a wide range of different grades and specifications. These shafts maximize torsion strength and contact area. Gamma Gears spline shafts are well acclaimed for delivering efficient performance, superb quality, flawless finish, exceptional durability and optimum resistance against corrosion. Spline shafts find extensive use in food industry, agriculture industry, printing industry, packing industry etc. Gamma Gears ensure fast, safe and trouble-free delivery of custom made shafts with our of well-coordinated transport system.

With having outstanding reputation in industrial engineering products manufacturing, Gamma Gears is also prime name as a spline gear shaft manufacturers in Ahmedabad, Gujarat, India. Our highly qualified, skilled and experienced engineers specially taking care for spline shaft design, spline shaft dimensions through spline shaft drawing.

WhatsApp us